Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Afrikaans

Afrikaans

wūěrdōuyǔ

wūěrdōuyǔ

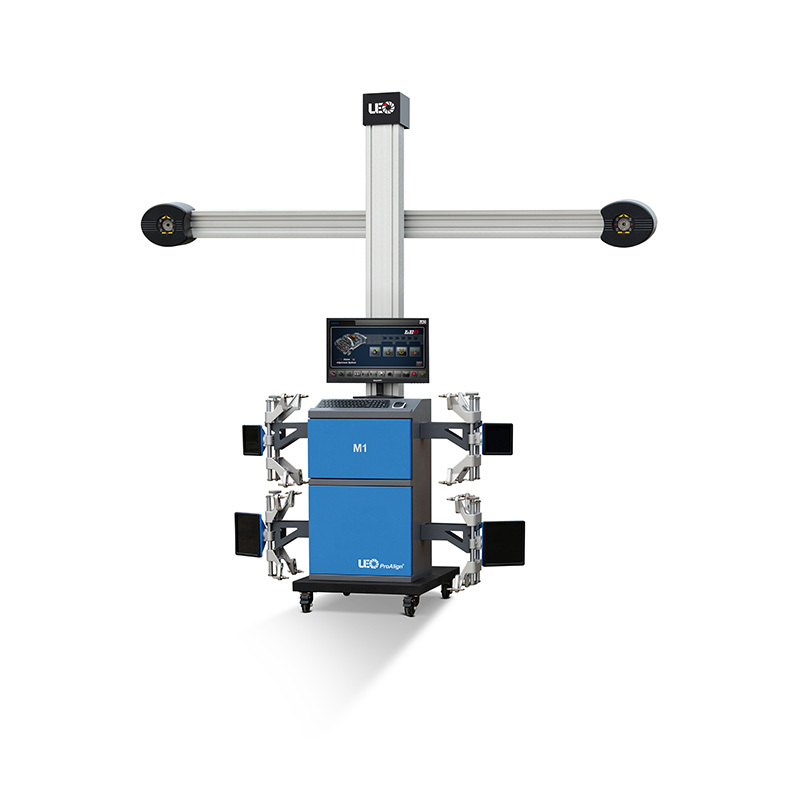

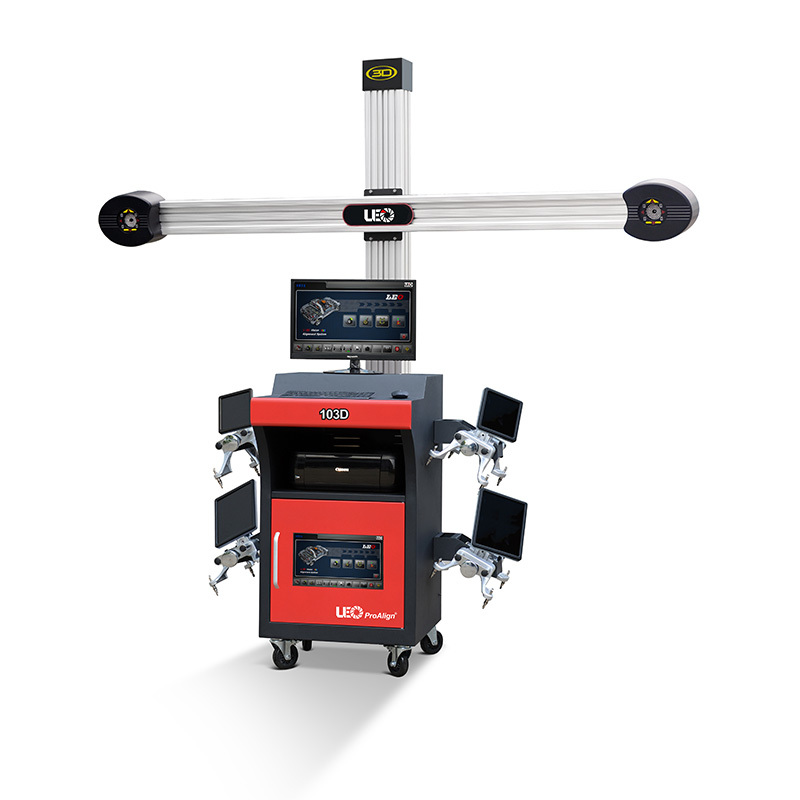

3D wheel alignment machine

3D wheel alignment machine is one of the main products of LEO Electronic & Technology Co., Ltd with good quality and Cheapest.Our factory is a professional suppliers and Manufacturers in China,Wholesale prices are available for customized products.

Category:

Product Description

Feature

√ Fixed aluminum alloy beam with 2 HD cameras

√ HD Camera with FPGA technology,and temperature compensation technology

√ Aluminum alloy column

√ Movable cabinet together with post

√ Cabinet can be moved together with the post and suitable for multi-station sharing

√ Industrial PC

√ 21" Screen monitor

√ Lightweight Shield targets

√ Very unique design software to provide fast accurate measurements

√ Professional result and high tech

√ Measurement feature (caster,camber,toe,steering angel )

√ Quick alignment,quick adjustment and quick printout report (Optional or self purchased printer)

√ Shortcut Key for quick check

√ Lift level check and remote diagnosis

√ Easy installation and flexible configuration

√ Automatic access to software and specification update

√ One step to finish four-wheel alignment positioning process

√ Online update database and alignment service

√ Optional Dual display system

√ Condition New

√ Software Independent

√ Language Global multi-language

√ Power Supply 110V~220V, 50/60Hz, 500W

√ Package Size Beam: 290*35*40cm

Cabinet: 85*71*122cm

Accessories: 60*66*103cm

√ Gross Weight 96+75+75=246kg

√ Warranty 1 year : Camera: 3 years

√ Trademark LEO

√ Origin China

3D wheel alignment machine is one of the main products of LEO Electronic & Technology Co., Ltd with good quality and Cheapest.Our factory is a professional suppliers and Manufacturers in China,Wholesale prices are available for customized products.

The 3D wheel alignment procedure is a comprehensive process used to accurately align the wheels of a vehicle using advanced three-dimensional technology. This procedure ensures that the wheels are properly aligned, which is crucial for optimal vehicle performance, tire longevity, and fuel efficiency. The process begins with the technician placing sensors or targets on each wheel, which capture precise measurements of camber, caster, toe, and other alignment angles. These measurements are then fed into a computer system that generates a detailed 3D model of the vehicle's alignment status. With this model, the technician can identify any misalignments and make necessary adjustments to bring the wheels back to their correct positions. The 3D wheel alignment procedure provides a more accurate and efficient method compared to traditional alignment methods, as it allows for real-time assessment and adjustment of multiple alignment angles simultaneously. By following this procedure, vehicle owners can ensure that their wheels are aligned correctly, promoting safer driving, reducing tire wear, and maximizing overall vehicle performance.

In the world of heavy duty truck alignment machine, ensuring the proper alignment of trucks is of utmost importance. Enter the heavy - duty truck alignment machine, a remarkable product that is changing the game in the truck maintenance industry.

The heavy duty truck alignment machine is specifically engineered to handle the unique requirements of large and heavy trucks. These machines are built with robust construction to withstand the substantial size and weight of heavy - duty vehicles. They are equipped with high - precision sensors that can accurately measure the alignment parameters of even the biggest trucks on the road.

One of the key features of this alignment machine is its ability to measure multiple alignment angles simultaneously. This includes the caster, camber, and toe - in/toe - out angles of both the front and rear axles. By providing comprehensive and accurate measurements in one go, it saves a significant amount of time for truck maintenance technicians.

For trucking companies, the benefits of using the heavy duty truck alignment machine are numerous. Firstly, proper alignment helps in reducing tire wear. Heavy - duty trucks often cover long distances, and misaligned wheels can lead to extremely uneven tire wear, which not only shortens the lifespan of tires but also increases operating costs. With the alignment machine, tires can last longer, resulting in substantial savings.

Secondly, correct alignment improves fuel efficiency. When a heavy - duty truck's wheels are properly aligned, there is less rolling resistance. This means that the truck's engine doesn't have to work as hard to move the vehicle forward, thus reducing fuel consumption. In an industry where fuel costs are a major expense, this is a significant advantage.

Moreover, proper alignment enhances the overall safety and handling of the heavy - duty truck. A misaligned truck can be more difficult to control, especially at high speeds or during emergency maneuvers. The alignment machine ensures that the truck drives straight and responds predictably to steering inputs.

The heavy duty truck alignment machine also comes with user - friendly software. The software provides clear and detailed reports on the alignment status of the truck. These reports can be easily understood by technicians and managers alike, making it easier to plan and execute maintenance procedures.

In conclusion, the heavy duty truck alignment machine is an indispensable tool for the heavy - duty truck industry. It not only improves the efficiency and cost - effectiveness of truck maintenance but also enhances the safety and performance of these large vehicles on the road. As the demand for reliable and efficient heavy - duty truck transportation continues to grow, the importance of this innovative alignment machine will only increase.

Movable Wheel Alignment Machines ProAlign® M1

Related Products

Welcome to leave a message